Machining Services

JPP provides turnkey part services. What we can offer is more than raw materials, you can rely on us to get customized services which includes, but not limited to, cutting, honing, rough turning, boring, skiving, polishing, etc. Our machining service can help save your time and cost even create more value to your products.

JPP always stands with clients. We have whole process quality control. From the raw materials to the delivery of finished products, we make sure every step is firm and safe.

Honing

Maximum OD:φ30mm~ φ500mm

Maximum Length: φ500mm~ φ12000mm

Straightness: 0.2~0.3mm/M

Tolerance Class: H8~H9

WT tolerance: ±5%

Surface toughness: Ra0.4~0.8μm

Deep Hole Boring and Skiving

Maximum OD: 15mm---950mm

Length range: 500mm--12000mm

Straightness:0.2~0.3mm/M

OD tolerance class: IT8

ID tolerance class: H8~H9

WT tolerance:±5%

Surface toughness:Ra0.05~0.2μm

Cementing tools and completion tools

Heat Treatment

JPP provides heat treatment services including annealing, normalizing, quenching, tempering, solution annealing, aging, precipitation hardening, along with mechanical property test, straightening, and non-destructive test.

Slotting

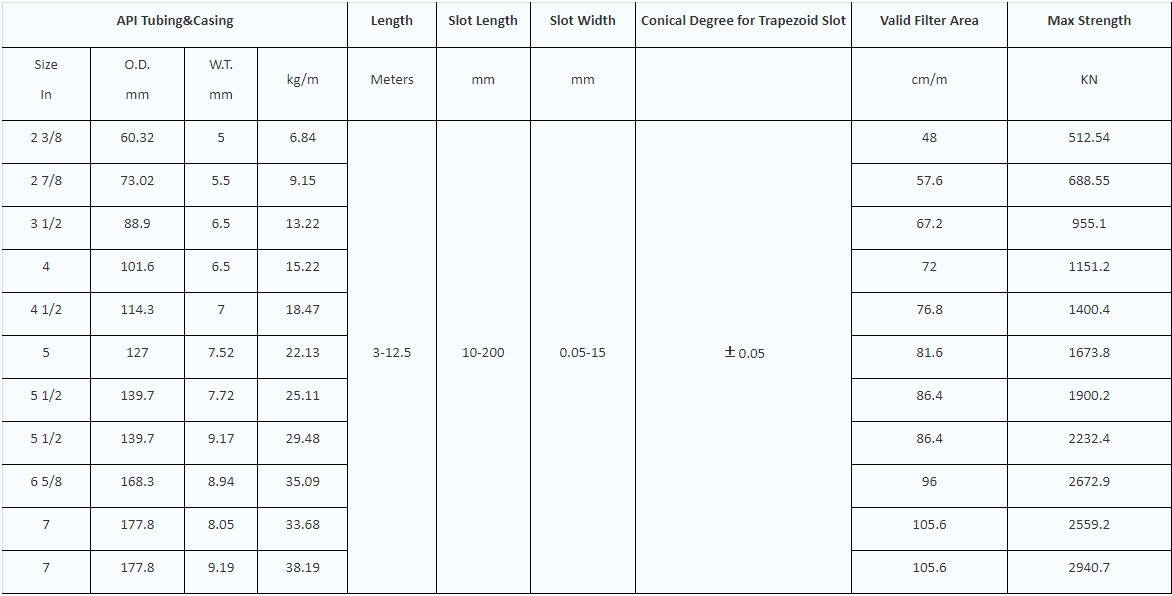

JPP designed and manufactured oil screen pipes, used in PDVSA's heavy oil well operations.

1.Slot Type: Straight Slot&Trapezoid Slot

2.Slot Pattern: Line Slot&Staggered Slot

3.Open Area: 2%-6%

4.Cutting Tools: Laser&Blade

5.Base Pipe: J55,K55,N80-1,N80Q,L80-1,L80-13Cr,T95,P110

6. Technical Data: